“I’ve seen some horror stories of people trying to do it on their own,” said Steve Kivel of New York’s Central Watch repair shop. If you put it all back together improperly, your watch could fall off your wrist. A slip of the wrist could scratch or dent the bracelet. But it’s still a frustrating task that requires finesse and calm. The pins and ferrules can be removed, either with affordable tools found online, or with whatever you’ve got in your junk drawer. That pin is, in some watches, paired with two small metal tubes called “ferrules” that hold it in place at both ends of the link. You have two courses of action: you can take it to a jeweler or repair shop and spend something to the tune of $20 to get it professionally sized, or you can take matters into your own hands.įortunately, most watch bracelets come with a pretty simple “cotter pin” system made up of a metal pin within a hole, which holds the links together. And unless you have Hulk-sized wrist, what you find is that the bracelet is a few links too big. You take it out out of the box, remove the stickers and try it on. For more information, please visit the American Watchmakers-Clockmakers Institute (AWCI).That watch you ordered - that cool, all-steel number - has finally arrived, after days of waiting.

#WATCH BRACELET COTTER PINS PROFESSIONAL#

Reprinted with permission from the Professional Jeweler Magazine. The other type (in a blue tube) allows the screw to be removed by hand. One variety (in the red tube) requires you to heat the link if you ever need replace it. If you tend to lose these screws or if they need to be replaced frequently, a drop of liquid metal glue called Lock-Tite will suffice. This will allow you to remove the old screw and insert the new one. If you see a specialised screw, you'll need to contact the manufacturer for the correct screw size and possibly a custom replacement device.

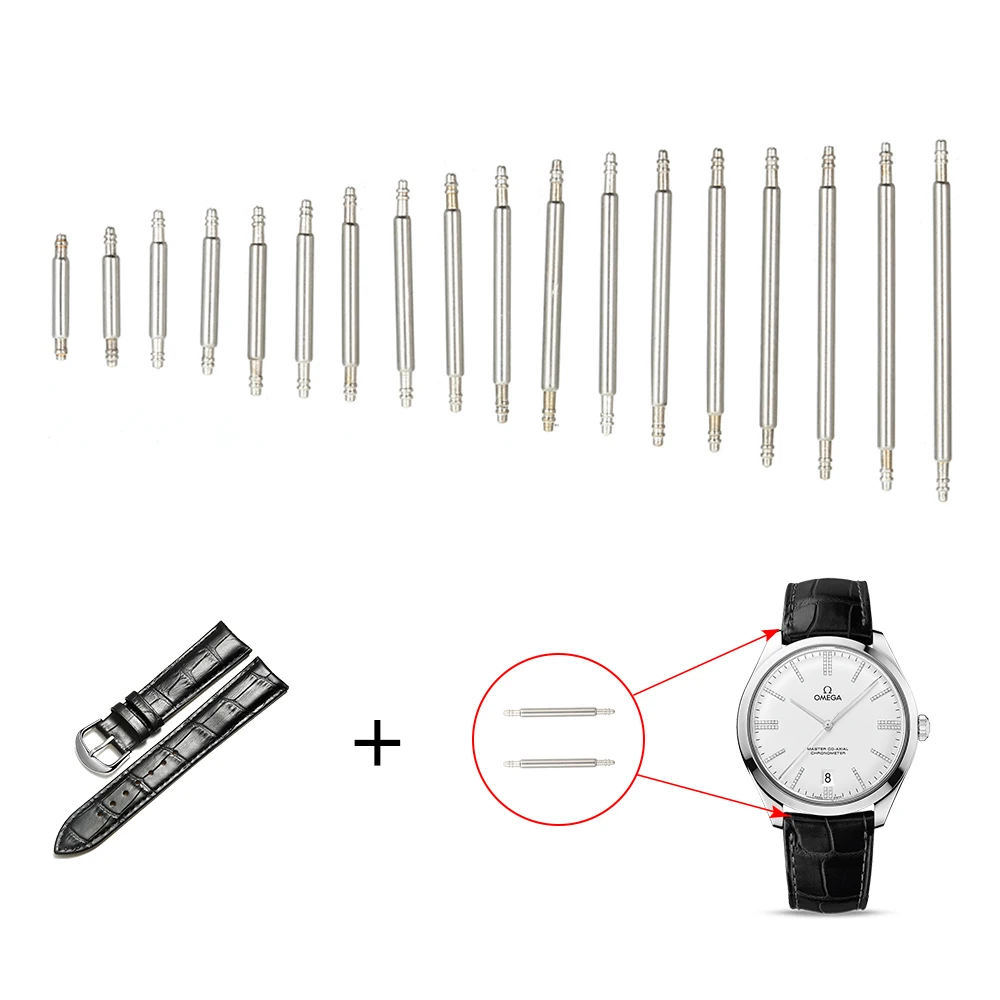

Locate the correct replacement pin from your supply and place it in the hole as the bracelet remains supported in a bench block. Measure the pin and note it for future reference if needed. If the pin is the type shown in the illustration on the right, take care not to lose the sleeves at either end. Grasp the end of the pin with your pliers and pull it out or gently move it side to side.

Choose a punch with the largest diameter that will pass through the hole at the edge. Drive the old pin out of its hole using a hammer on a punch. Place the bracelet in a staking tool or tool supplied by the watch manufacturer.

Less common is a pin held in place by a small sleeve at each end (see illustration on the left for a view of this pin from the edge of the link).įor either type of common pin, the replacement process is the same. The outline may appear to be a screw, but more likely you're seeing the line created by a split pin - which resembles a cotter pin. Rotate the edge under a sharp light to see the outline of the end of the pin. In some cases it's flush with the edge of the link - particularly on finely polished models.

Several wellknown watch brands supply a link-pin remover when you first work with their watches.įind the old pin. All can be removed quickly using a thin punch in your staking tool or by using a tool supplied by the watch manufacturer. Some pins are smooth, some are ribbed and some resemble cotter pins, where one end splits open to tighten it in place. Pins are the most common method used to hold links together.

#WATCH BRACELET COTTER PINS HOW TO#

Here we cover how to use link-pin tools to quickly replace the lost or bent metal link in your bracelet. In recent articles we've covered mesh varieties and how to fit links back onto cases. The link bracelet is held together in several ways. By David Christianson, Certified Master Watchmaker

0 kommentar(er)

0 kommentar(er)